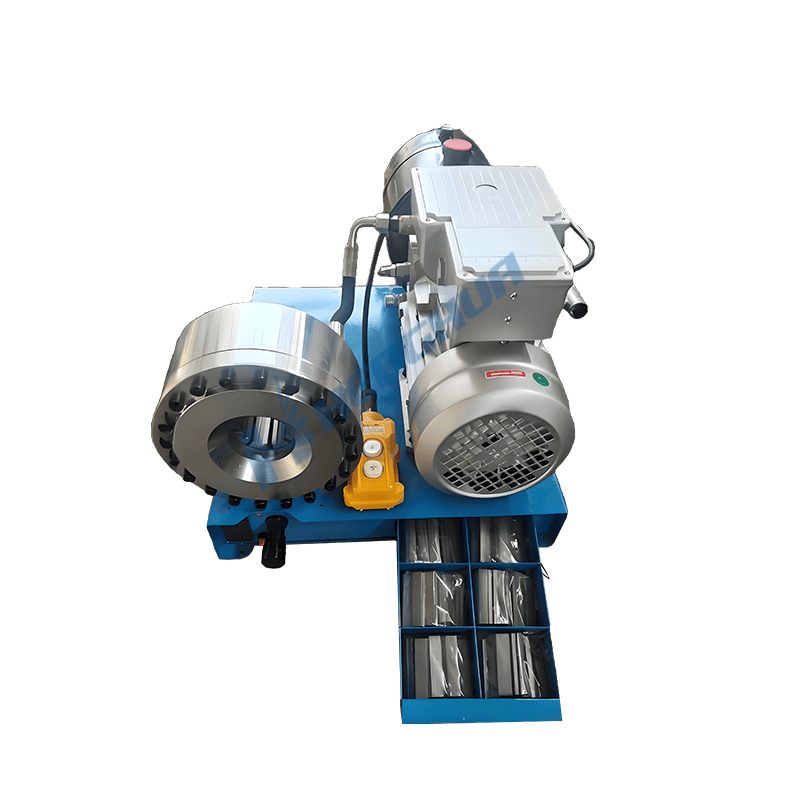

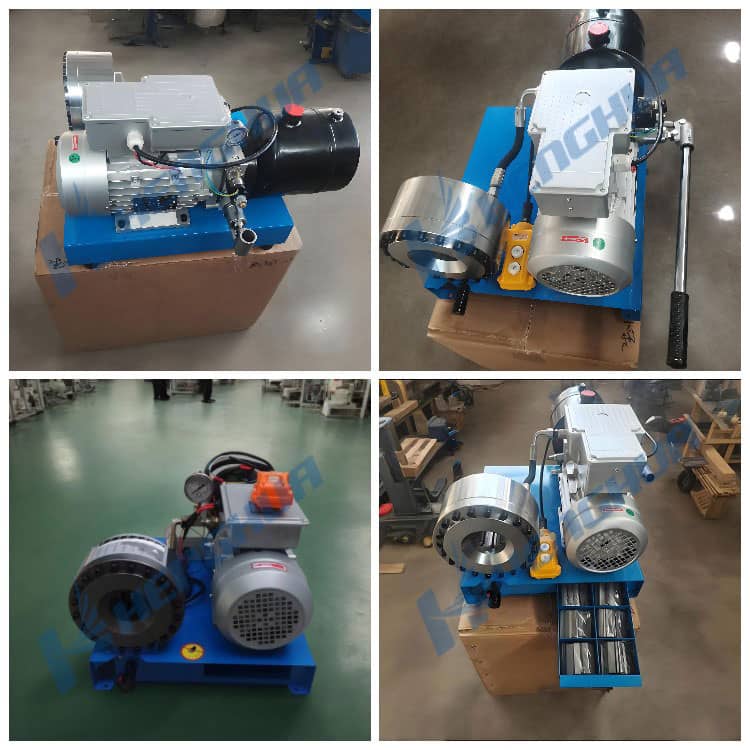

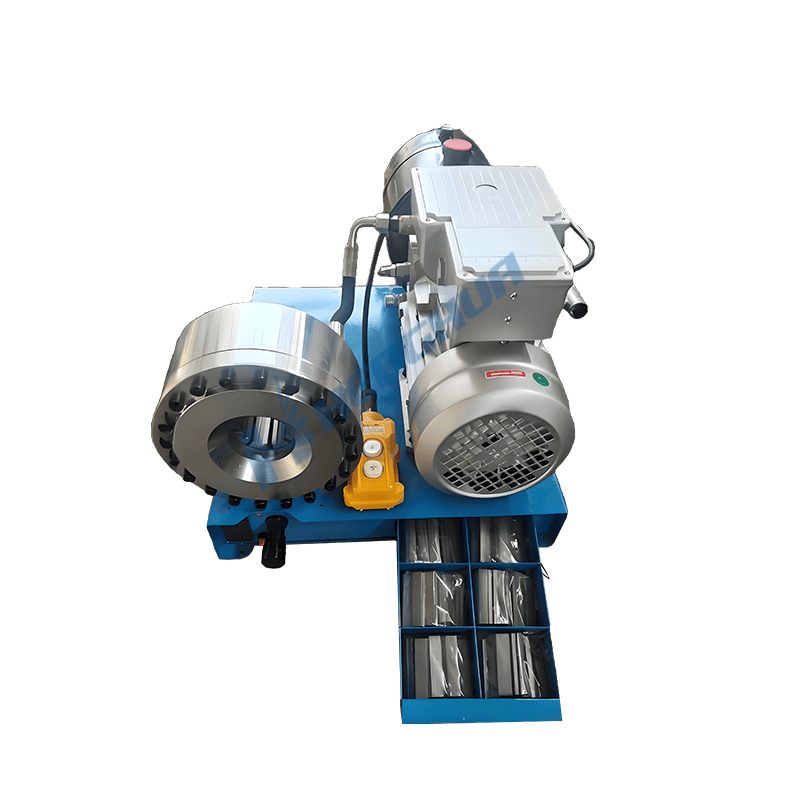

This electric hydraulic hose crimping machine is designed to provide precise top crimping solutions for hydraulic equipment. Made of high-quality steel, it is strong and durable, has excellent fatigue resistance, and is suitable for top crimping work of various specifications.

Features:

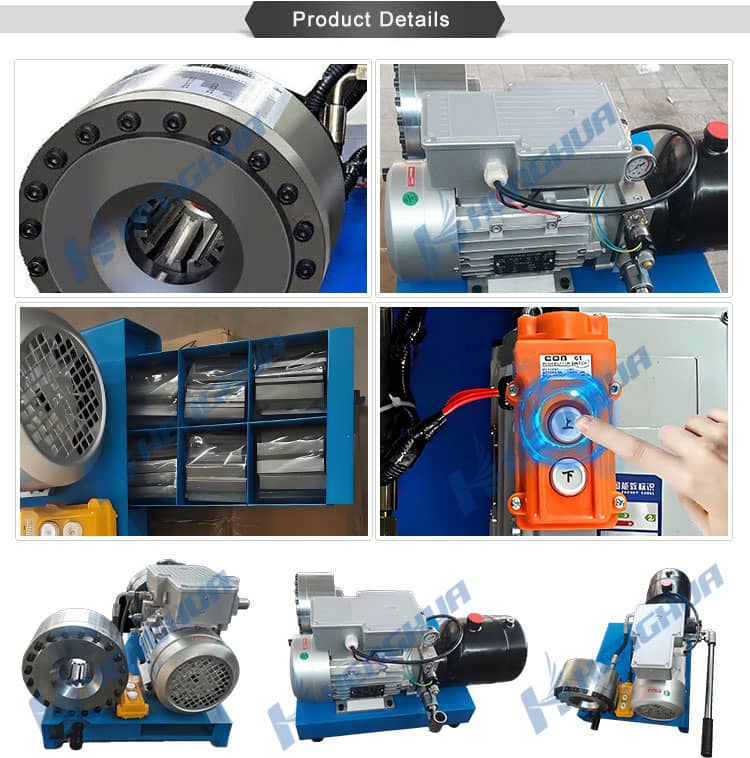

1.Wide range of applications: Supports hose crimping with inner diameters from 6 to 25 mm (1/4 to 1 inch), has good compatibility, and can meet the needs of different equipment.

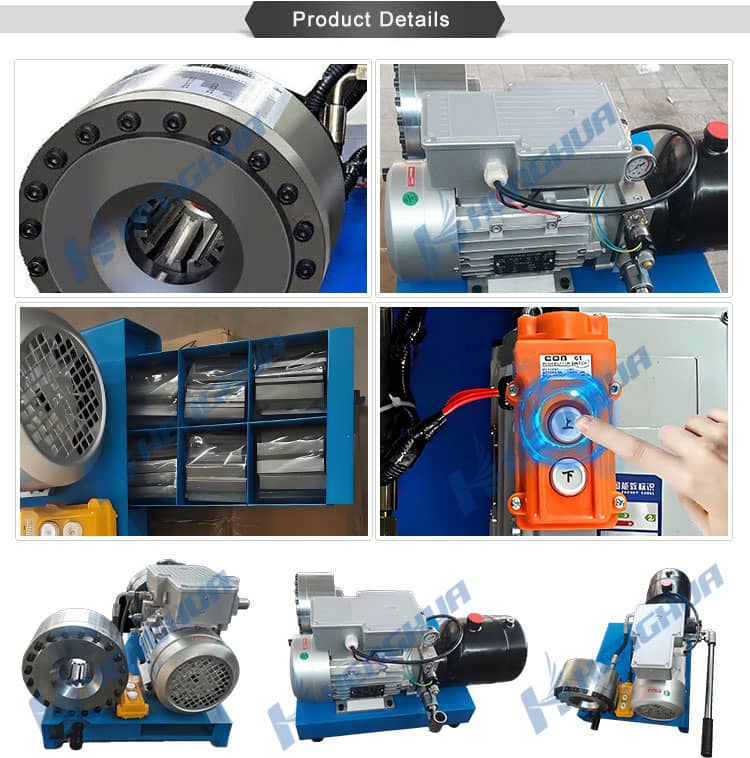

2.Rich mold configuration: 8 sets of molds are standard (10mm, 12mm, 14mm, 16mm, 19mm, 23mm, 27mm, 31mm), suitable for hoses of various diameters to achieve multi-purpose applications.

3.Easy operation: Using an electric motor as the driving source, the operation is simple and convenient, saving labor costs.

4.Powerful mold opening capability: The maximum opening can reach 55 mm without a mold, and the maximum mold opening is 25 mm, ensuring good adaptability and flexibility.

5.Energy-saving and efficient: Power 2.2 kilowatts, high energy efficiency ratio, reducing energy consumption.

6.High-quality materials: Made of high-quality steel, it has excellent mechanical properties and extends the service life of the equipment.

7.Limit valve design: The equipment is equipped with a limit valve to effectively control the crimping stroke, prevent hose damage caused by over-pressure, and ensure crimping accuracy.

8.Intuitive monitoring: Equipped with a hydraulic gauge to monitor the system pressure in real time to ensure that the operator can grasp the working status at any time and improve safety.

|

Brand |

HENGHUA |

|

Number of dies |

8 sets (10mm, 12mm,14mm, 16mm, 19mm, 23mm, 27mm, 31mm) |

|

Crimping range (inner diameter) |

6-25mm (1/4-1inch ) |

|

Model |

Electric Hydraulic Hose Crimping Machine |

|

MPN |

Does not apply |

|

Country/Region of Manufacture |

China |

|

Compatible Equipment Make |

Universal |

|

Part Type |

Hydraulic Pump & Pump Parts |

|

Compatible Equipment Type |

6-25mm |

|

Model Year |

6-25mm pipe |

|

Material |

Steel |

|

California Prop 65 Warning |

No |

|

Unit Quantity |

1Set |

|

Unit Type |

Unit |

|

Operation mode |

Electric motor |

|

Power |

2.2KW |

|

Opening without molds |

55mm |

|

Molds max Opening |

25mm |

|

Package |

Wooden box |

|

Transport |

International express delivery DHL or FedEx |

Instructions for use:

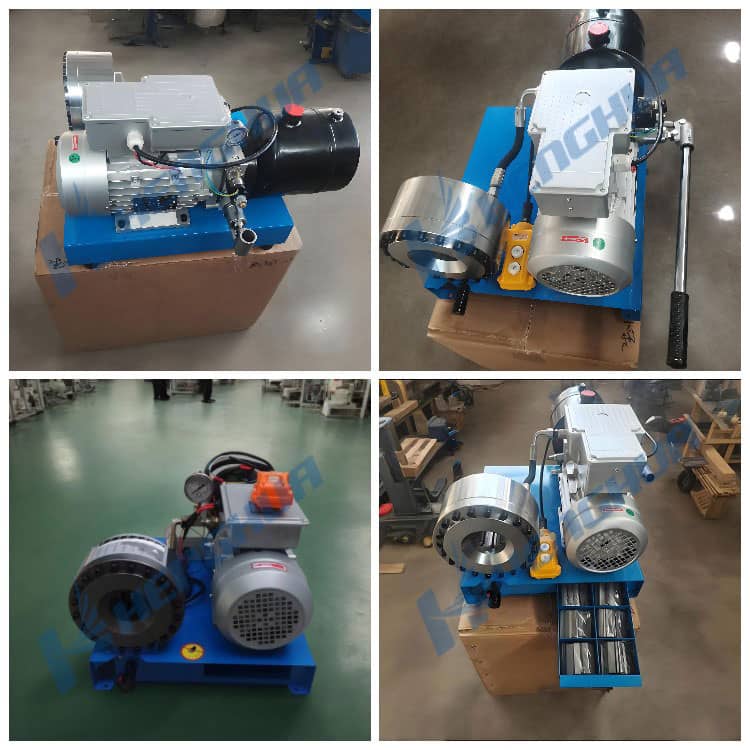

1. Please add hydraulic oil before first use.

Before starting the machine for the first time, be sure to add an appropriate amount of hydraulic oil to the tank.

2. The oil level should be maintained at about 30 mm from the oil tank mouth (do not start the machine before adding hydraulic oil).

When refueling, please pay attention to the amount of oil and ensure that the oil level is at an appropriate height to avoid damage to the equipment due to insufficient oil.

3. Please connect the power supply correctly.

Before use, please ensure that the power cord is correctly connected to avoid safety hazards caused by power problems.

4. During use, please pay attention to the temperature of the fuel tank and motor.

If you find that the temperature of the fuel tank or motor is too high, please stop using it immediately and wait for the temperature to drop before continuing.

5.Micrometer adjustment:

The processing size of the machine can be set by adjusting the micrometer. The machine will automatically stop when the preset size is reached.

6. During use, please keep the oil filler nut loose (for better air circulation). Please tighten again after use.

During use, to ensure good ventilation, please do not tighten the oil filler nut and re-tighten it after use.

7. The UP key on the operating handle controls the mold to close, and the DN key controls the mold to open.

During operation, please follow the instructions and use the buttons on the handle to control the movement of the mold.